Solutions that optimize the installation, accuracy, and service life of your equipment.

At Flexilatina, we offer a complete and comprehensive portfolio of accessories designed to complement and protect your pressure instruments. Each component fulfills a specific function that contributes to reliable and safe performance in any industrial application.

Diaphragm separators (chemical seals)

Available in sanitary, flanged, threaded, and other special connections. Made from 304, 316L, 316 stainless steel, Monel, Hastelloy, and other materials, as well as special coatings such as PTFE, PFA, and gold.

For each separator application, we offer the perfect design, material, and filling fluids.

They prevent direct contact between the medium and the instrument, protecting it from corrosive, viscous, or high-temperature fluids.

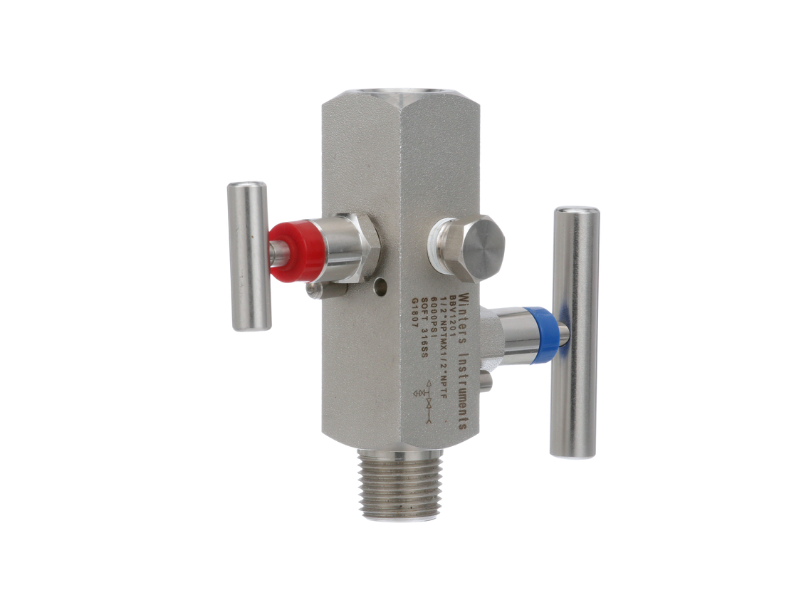

Needle valves and Purge valves

Pressure measuring instruments can be safely separated with our lockable and purgeable needle valves. Available with one (1) to three (3) handles (valves) with threaded and/or flanged connections as a monoblock or monoflange valve.

In addition, with special requirements such as: NACE MR0175 / ISO 15156, if required.

They allow the instrument to be isolated and trapped pressure to be evacuated. They facilitate maintenance and improve operational safety.

Capillary extension (Capillaries)

These are flexible stainless steel tubes that allow the instrument to be separated from the measuring point, protecting it from heat, vibration, or aggressive environments.

Available lengths: from 0.5 m to over 10 m with threaded connections or others as required.

Applications: Boilers, furnaces, hot fluids. Chemical or corrosive processes. Installations with remote access or control panels.

3- and 5-way manifolds (valves)

For differential pressure measuring instruments (differential pressure gauges or process transmitters)

They integrate isolation, purge, and equalization functions in a single compact body. Ideal for differential pressure transmitters.

Used in: Filtration systems, gas lines, critical processes where precision and safety are required.

Cooling towers and Siphon tubes (Pigtail)

Cooling Towers are finned metal cylinders or specially designed cylinders that reduce temperature by convection.

Siphon tubes form a loop in which condensate accumulates. This condensate acts as a thermal barrier, preventing steam from reaching the instrument directly.

They improve reading stability under variable thermal conditions and extend the service life of the instrument. They are used in steam, boilers, and industrial thermal processes.

Snubbers (Pulse dampeners) and Overpressure protectors

Snubbers reduce the impact of overpressures and pulsations in process lines, protecting the internal mechanism of the instrument.

Overpressure protectors are devices that protect the instrument from sudden pressure spikes that could damage it or alter its reading.

Used for hydraulic and pneumatic systems, pulsating fluids. Chemical, food, and water treatment plants.

Other accessories

Include: Flushing ring, Thread adapters, Reducing bushings, Flange for panel mounting, and Laminated safety glass for pressure gauges.

Pressure instruments compatible with Accessories

Mechanical pressure gauges / Digital pressure gauges / Process transmitters / Pressure transmitters / Differential pressure transmitters / Electronic or mechanical pressure switches / Pressure transducers.

Benefits of using accessories in pressure instrumentation

- Isolation of the instrument from the process

- Diaphragm separators, with capillaries or cooling towers, isolate the instrument from aggressive, viscous, corrosive, or solid-laden process media, preventing premature damage and extending the device’s service life.

- Protection against high temperatures

- Accessories such as cooling towers, siphons (pigtails) or capillary extensions protect instruments from high process temperatures by dissipating heat before it reaches the pressure sensor.

- Reading stability and error reduction

- Snubbers (pulse dampers) and needle valves reduce the impact of water hammer, pulsations, or pressure spikes, stabilizing the reading and preventing sensor failure.

- Facilitates maintenance and calibration

- Lock, purge, or manifold valves allow the instrument to be easily disconnected without stopping the process, simplifying verification or replacement tasks without compromising operational safety.

- Improved operational safety

- The use of overpressure protectors and appropriate valves reduces the risk of leaks, overpressures, and unwanted mixing between lines, protecting both instruments and personnel.

- Adaptability to complex or sanitary media

- For applications in the food, pharmaceutical, or chemical industries, sanitary separators, clamp connections, SMS, or DIN connections, among others, ensure residue-free cleaning, resistance to CIP/SIP, and compliance with hygiene standards (3A, FDA, EHEDG).

- Regulatory compliance

- All these accessories are available with certifications or manufactured to recognized standards such as ASME, NACE, EN, and ISO, or even with specific tests such as helium leak tests or pressure tests to ensure their integrity in operation.

Not sure which accessory you need?

Our technical team is ready to advise you and help you select the right solution based on the process, fluid, and installation conditions.

Contact us today for expert support or to request a quote for our instrumentation accessories.

Accessories for pressure instruments